17 Apr 2019 Vacuum soldering is like an award winning cousine

Over the last 20 years, flux-free and paste-free vacuum soldering with preforms and formic acid has gained high importance for electronics packaging. Especially for big area solder joints within power modules for electric cars, this soldering technology can achieve void rates below 1%. This would not be possible with conventional paste soldering. However, the flux-free soldering technique has higher requirements on the material quality. To give a better understanding, this article uses award winning cuisine by way of example.

Soldering and cooking process flows

Flux-free soldering with preforms and outstanding cuisine are quite similar.

- Well-trained employees are necessary for innovative processing

- Modern tools and equipment enable the best quality of the final product

- Fresh ingredients will generate excellent results

Equipment: The cooking plate

For a better understanding of preform soldering, the comparison with cooking for a gourmet restaurant is quite suitable. First of all, a cooking plate (hot plate) with an electrical heater or cartridge heaters is required. The temperature range of the cooking plate must be adjustable up to 450°C.

Equipment: Soldering chamber

Next, the restaurant needs a pressure cooker. It is similar to the soldering chamber. Ingredients, such as meat or potatoes (soldering devices) are placed in the cooker (chamber). Atmospheres and pressure levels can be adjusted within the cooker.

Temperature control through direct-contact heating

By controlling the temperature of the cooking plate (heating power) and by placing the pot on or removing it from the plate, the temperature within the pot is regulated and a soldering profile is achieved. By forcefully pressing the pot onto the plate, the heat transfer will improve and the ingredients will heat up faster.

Temperature profile

While cooking, the temperature is often increased for a short moment to start the Maillard reaction. This reaction creates rich flavors (melanoidins), which make for an outstanding meal. At soldering, the liquidus temperature serves a similar cause. The solder starts to fuse with the device and has to be cooled down as soon as possible to avoid damaging the device. As with cooking, if the Maillard reaction is too strong, the ingredients will burn.

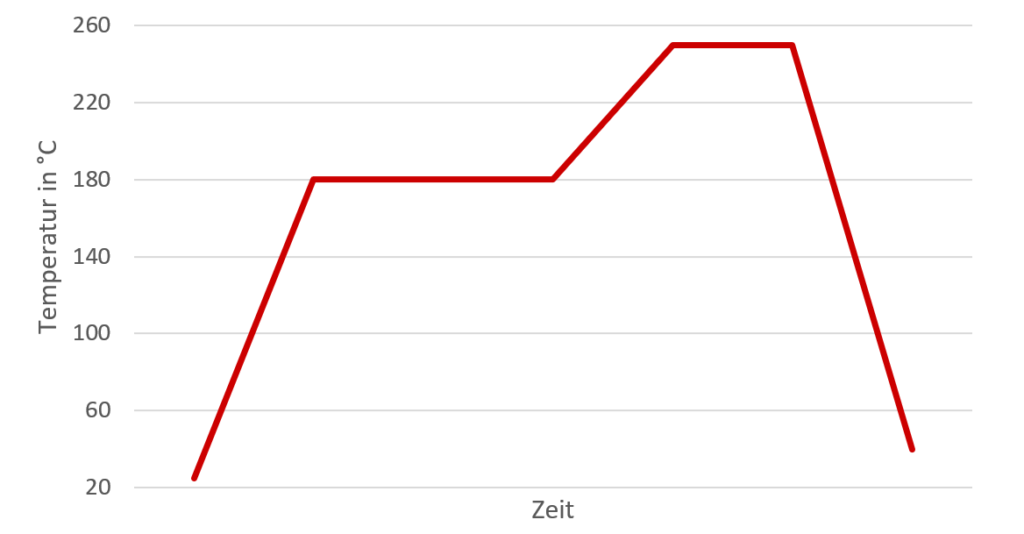

By taking the pot from the heater, its content starts to cool down. Cooling the pot under running water is comparable to water cooling at soldering. Figure 1 shows a formic acid soldering profile for tin solders. Firstly, the product is preheated to 180°C to ensure a good effect of the formic acid. Afterwards, the solder is liquified at 250°C and then cooled down rapidly.

Figure 1: Formic acid soldering profile with tin-based solders

Spices and formic acid

The right use of spices makes the meal taste great. The oil within the spices evaporates and sticks to the meat and potatoes. Formic acid or hydrogen serves a similar cause at soldering. The acid evaporates and cleans the surfaces to ensure a good wetting of the solder.

What process engineers can learn from gourmet chefs

As we have seen, the success of an award-winning cuisine and soldering process depends on the ingredients and tools:

- Only fresh ingredients lead to success: Over-stored (rotten) materials must be avoided

- With the best ingredients you can achieve the best results for your customers

- Avoid contamination of the product by wearing gloves.

- Do not use sharp tools: By poking the meat with a fork, it loses its juices and becomes dry. At soldering, scratches caused by sharp tools negatively influence the wettability

- Only use clean tools! How good can the steak be, if there was still old oil in the pan?

- Every hair in the soup bothers your guest (creates voids in the interconnect): A cleanroom with special preparations is mandatory for sintering. Compared to soldering, the requirements for cleanroom classes, employee training, cleaning intervals, etc. are much higher. Cooking times instructions must be followed. Incautious acceleration of the time leads to low quality. The product is burned on the outside but raw on the inside.

- The product temperature is critical for success. Everybody knows the problem: You have a new oven and your recipe are no longer working. The reason for this is that the temperature profile of the new oven differs from the old. Therefore, always check the product temperature (not oven temperature) and distribution.

- Keep an eye on the atmosphere: For flux-free soldering, the atmosphere’s composition (oxygen content, sulfur content, organic outgassing) is crucial for success. If you place a glass of water in the oven, the bread will get crunchy and tasteful. If you have remains of cleaning agents in the oven, the bread will be horrible.

- Watch the cooling processes: Cooling too quickly can destroy glasses. If the cooling takes too long, however, your guests will be in a bad mood. Nobody wants to wait long for their meal!

- Keep the storage conditions in mind: The potatoes might have been delicious when they came out of the oven. But after keeping them in the oven for another two hours, they will be burnt and inedible.

- Also keep the storage conditions in mind: Even if the potatoes were tasteful after baking – two hours stored with a too high temperature in a bread box is will be soft and disgusting.

Conclusion

Attention to detail is just as important for gourmet cuisine, as it is for paste-free vacuum soldering with preforms and formic acid. Investing in high-quality materials and processes, as well as in a thorough training of employees will pay off and lead to happy customers.

This might also be interesting for you

Do you have questions regarding vacuum soldering? Do not hesitate to contact us.