08 May 2023 Sintering introduction support for newcomers

You want to introduce sintering into your company? A sintering line can easily cost 2.000.000 (two Million) Euro. To save investment and time to production, we support our customers on specifications, machine and material selection as well as pre-trials and product design for sintering. In later stages we help our customers to prevent yield losses and downtimes during production. As material costs compared to solder paste are ~50x higher for Ag sintering, maximizing yield and minimizing downtime are key factors for an economically successful sintering line. We help you to achieve that!

We offer you:

- An overview of sintering materials and its requirements on surfaces, atmospheres

- Process knowledge: wet- and dry pressure sintering, pressure-less sintering, large area sintering

- Experience with sintering machines: Required equipment for pre- and postprocessing, sintering presses and sinter tooling

- Quality inspection of a sintered joint

- Guide how to select a sinter paste, a pick&place and a sintering machine

- Workshops and support for product design for sintering

- Accellerated material and equipment supplier selection

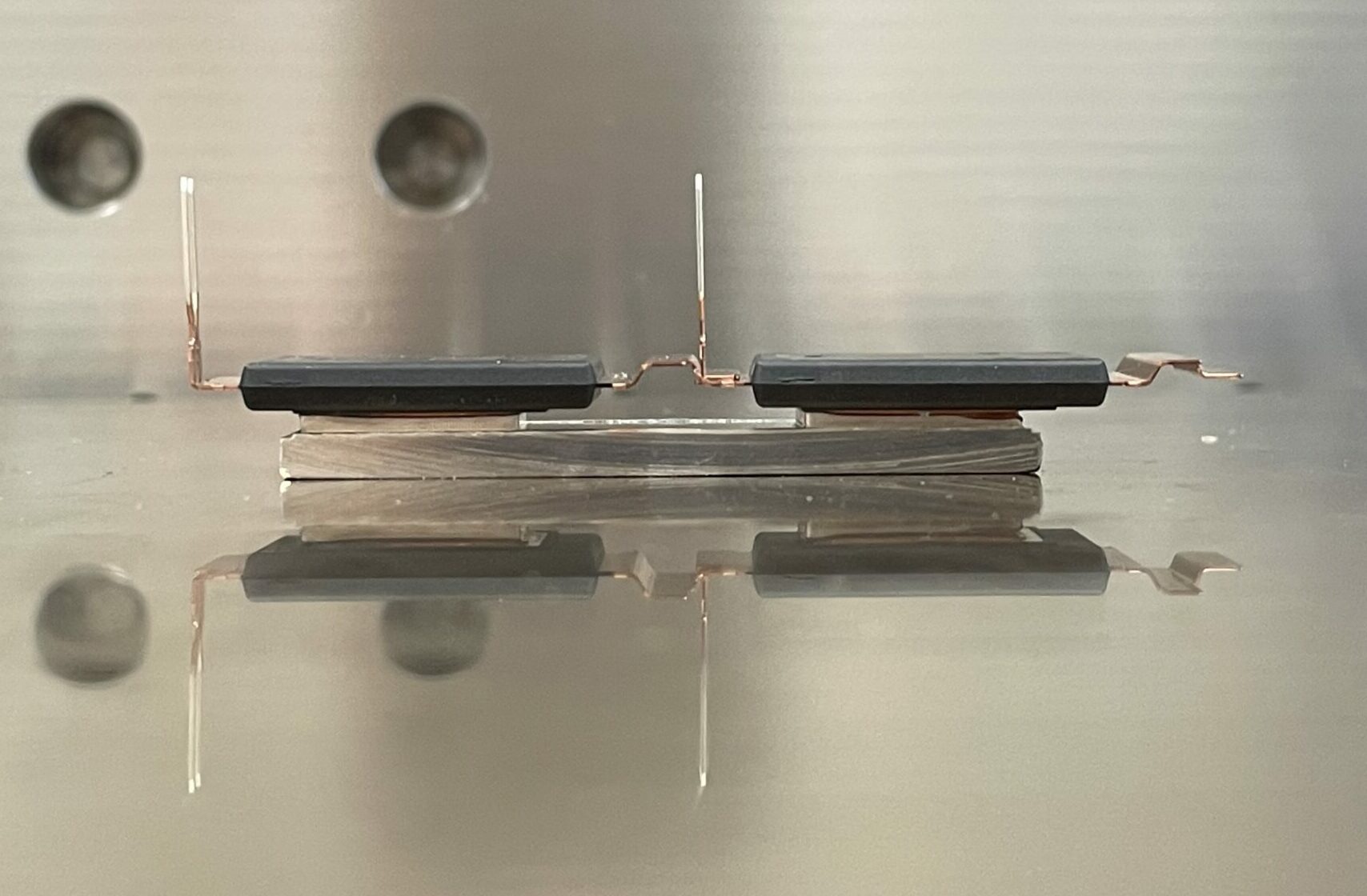

- Prototype assembly

Questions answered for other customers

- What are the typical process parameters for silver sintering that affect thermal and lifetime performance?

- Which surfaces properties effect the sinter bond thermally and in lifetime performance?

- What are the pros and cons of copper sintering vs. silver sintering?

- What are the pros and cons and considerations when sintering in air or under N2/vacuum atmosphere?

- What are the differences between a pressure and pressure-less sintered bond?

- What equipment can be used for pressure-less and pressure sintering

- What has to be considered when design a product for sintering that has been soldered previously?

Interested?

Contact us today.